Techniques

Selecting the most appropriate remediation technique for a specific site depends on numerous factors such as the type and characteristics of the contaminant, the soil, the groundwater, the geochemistry and the natural degradation. The presence of buildings, professional activities or access to the problem area also have an impact on the selection. Based on its experience, Sodecon can select, elaborate and implement the most appropriate remediation technology or combination of technologies for a site.

- Excavation

- Soil vapour extraction and air sparging

- Pump & treat

- In situ chemical oxidation (ISCO)

- In situ chemical reduction (ISCR)

- Stimulation of biodegradation

- In situ metal precipitation

- Injection technologies

- LNAPL and DNAPL removal

- Thermal techniques

- Risk management measures

- Innovative techniques

Excavation

However, complex soil contaminations, with chlorinated solvents for example, are generally characterized by (i) a highly concentrated, but relatively small source of contamination, and (ii) a diffuse, low-concentration plume, that can be very large. In this case, excavation can be used to eliminate the smaller concentrated source of the contamination. When eliminating the source zone, the largest part of the contaminant mass is removed. Moreover, leaching of contamination to the plume is stopped by removing the source. During removal of the source zone, the strategic planning and execution of the dewatering system are extremely important to reach the remedial objective.

Excavation is much less suited to treat the contaminant plume. Due to lower contaminant concentrations in the plume, less contaminant mass is removed and efficiency decreases (kg contaminant mass/cost €). In most cases, the plume will be treated with an in situ technique in which the soil is not excavated but is treated on site.

Soil vapour extraction and air sparging

Air sparging involves the injection of compressed air into the soil to volatize the contamination in the saturated zone. It can be used for soils contaminated with volatile compounds such as BTEX and chlorinated solvents. This technology will also bring oxygen into the soil that can stimulate the biodegradation of aerobically biodegradable contaminants. It is combined with a soil vapour extraction system to capture the vapours in the vadose zone. Airsparging is sometimes only used for stimulation of the aerobic degradation of the contamination. This usually occurs at lower flow rates and is called ‘biosparging’.

Pump & treat

The technology can also be used to lower the water table in order to increase the vadose zone. In this way, soil can be excavated below the water table and volatile contaminants can be more easily removed by soil vapour extraction. The combination of pump & treat and soil vapour extraction is called dual phase extraction.

In situ chemical oxidation (ISCO)

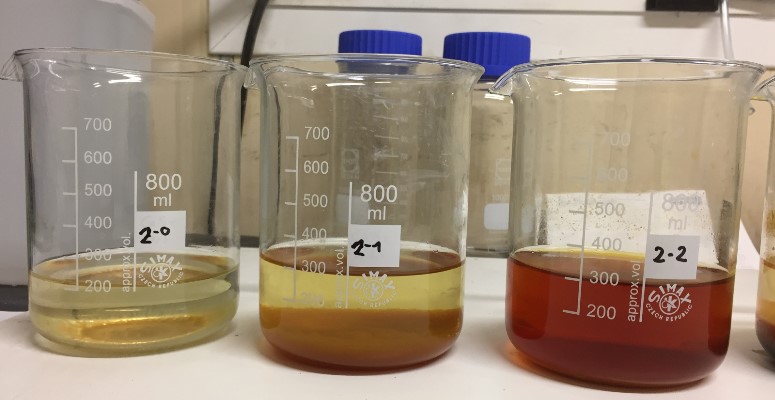

Chemical oxidants will also react with the soil matrix. The amount of oxidant consumed by the soil is usually significantly higher than the amount of oxidants needed to destroy contamination. A determination of the soil oxidant demand in lab before field application is in a lot of cases recommended in order to determine the economic feasibility of the technology and to determine the required dosing for a site. Sodecon performs these tests in its own treatability lab.

In situ chemical reduction (ISCR)

The most well-known application is the use of zero valent iron to destroy chlorinated solvent contaminations. The disadvantage of iron is that it is not soluble and as a consequence it can not be easily injected into the soil. The following applications are possible:

- Slurry injection as microscale iron: a particle slurry is injected into the soil to treat the contamination. During injection, fractures are created in which the slurry is injected.

- Slurry injection as nano-iron: nano-iron particles are smaller than the soil pores and can therefore be injected more easily than microscale iron. It is however more expensive than microscale iron.

- Permeable reactive barrier: granular iron is being applied in a trench perpendicular to the groundwater flow. Contaminated groundwater flows through the trench and is treated by the iron in the trench.

Stimulation of biodegradation

- Oxidative stimulation: an electron acceptor is added to stimulate the degradation of the contamination. Oxygen is the most frequently used acceptor, but also nitrate and sulfate can be injected as an electron acceptor. The most well-known application is oxidative stimulation of petroleum/BTEX compounds.

- Reductive stimulation: an electron donor is added to create reductive conditions in the soil. Under these conditions the contaminants are consumed as an electron acceptor by specialized bacteria. This method is very often used for the reductive destruction of chlorinated solvents.

- Bioaugmentation: this strategy involves the injection of bacteria into the soil with the degradation capacity to destroy the contamination. This strategy is only used when the natural degradation capacity is not present and is always combined with either the stimulation of the oxidative or the reductive processes.

In situ metal precipitation

- Biological precipitation: by the addition of a carbon source, sulfate is reduced to sulfide which subsequently precipitates the metals onto the soil matrix

- Chemical precipitation: Sulfide can also be injected as a chemical to precipitate the metals onto the soil matrix

- Alkaline precipitation: the addition of hydroxide can precipitate the metals as hydroxides

Injection technologies

- Direct injection: with this technology, a substrate is injected into the subsurface while advancing an injection rod into the soil. The injection product is injected through holes at the bottom of the injection rod. There are different methods of direct injection: direct push injection, Spin® injection,… that can be applied depending on the site specific circumstances. Compared to the other technologies, this method allows for injection in low permeability soils and for the injection of slurries.

- Injection on infiltration wells: With this method, injection substrates are injected in a screened well. Good well installation is crucial for optimal performance. Sodecon especially focuses on the installation of a good well seal. This method is recommended when high volumes need to be injected multiple times. This method is preferably used in homogeneous soils.

- Injection on drains: When access to a site is limited, drains can be installed by horizontal drilling in order to install a system in areas that are difficult to reach. Drains allow for the injection of high volumes in permeable soils.

- Recirculation: This method is a combination of injection wells/drains and extraction wells/drains. Steering is more complex as extraction pumps are needed and measures to avoid clogging need to be put in place. The advantage of this method is that no external water source is necessary and that large plumes can be treated as continuous recirculation is possible.

- Soil permeability: low permeability soils will require other technologies than high permeability soils

- Soil heterogeneity: a different strategy is needed for homogeneous soils compared to heterogeneous soils with an alternating sequence of high and low permeability layers.

- Groundwater velocity: the groundwater flow rate will determine when the injection substrates will be washed out of the soil and when a new injection is necessary.

- Depth of treatment: when treatment of deeper soil layers is necessary, it will be more favorable to install permanent wells instead of temporary wells.

- Injection substrate: soluble substrates or emulsions are more easy to inject. Particulate substrates are more difficult to inject and need to be injected by a fracturing method.

LNAPL and DNAPL removal

- Skimming: dependent on the level of groundwater and the amount of contamination, different skimming strategies can be used (periodic pumping, continuous pumping with aboveground or underground pumps).

- Surfactant flushing: a surfactant can be injected into the soil, in order to make the contamination more mobile. The surfactant/contaminant mixture is subsequently extracted. This cycle is repeated until the pure product is removed.

- Absorption socks: when the amount of pure product is small, absorbent socks can be applied into a well to sorb the contamination present.

Thermal techniques

- Electrical resistance heating: Electrical current is passed through a volume of soil. The soil is heated because of the resistance of the soil.

- Conductive heating: By heating a heating element in the soil, the heat diffuses from the point of heating into the soil until the required temperature is reached.

- Convective heating: This method involves the injection of steam, hot air or hot water into the soil. Therefore this method is most suited for permeable soils.

Risk management measures

- Groundwater pumping system at the edge of the contaminant plume

- Installation of a vapour barrier inside a building

- Impermable clay mats on the bank of a stream

Innovative techniques

- Automatic pressure control system for continuous injection on injection wells

- Application of sulfate for the treatment of BTEX compounds

- Application of persulfate for treatment of MTBE and monochlorobenzene

- Development of a new surfactant for surfactant flushing

- Thermal bioremediation of BTEX/petroleum compounds

- In situ treatment options for cyanide

- 1,4-dioxane: development of a new type of aboveground reactor as an alternative to a UV/hydrogen peroxide reactor

- PFAS: development of new technologies for water and soil treatment

SODECON is an innovative, knowledge-based company specialising in soil remediation providing consultants, developers, industrialists, and private individuals with lasting, economic solutions to their soil issues.

.png_tmp.png)

Contact us

Galileilaan 15 – B-2845 Niel

Magazijn Deinze :

Souverainestraat 14 – B-9800 Deinze

+32 3 443 05 60

info@sodecon.be

Privacy Policy | 2014 © All Rights Reserved. Creatie 123websites.be